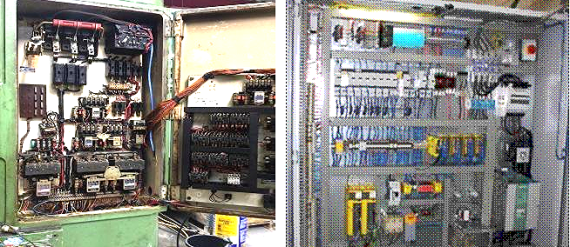

A limited budget for new machines means that refurbishing equipment can be cost effective by giving a new lease of life to existing machine tools.

· New machine controls & electrical systems

· CNC controls

· Slideways

· Motors & drives

· Lead & ball screws

· Spindle refurbishment

· Tool changers

· Pallet loaders

Interaxis now carry a large stock of Turcite B and adhesive.

Turcite B is a low friction linear bearing strip material for use on slideways, keep plates and gibs on machine tools. It provides low friction, stiction free operation with long life and minimum wear.

Turcite B is applied using a two part epoxy resin straight onto the metal surface.

Interaxis use Turcite for the refurbishment of worn/damaged faces on all types of conventional & CNC machine tools.

Turcite B is easy to machine/grind & scrape back to size and is dimensionally stable, maintenance free and can be used in an environment with or without lubrication.

Turcite B can be used on large and small machine tools, both CNC & conventional types under heavy & light machining conditions.

Features and Benefits of Turcite B

• No stiction helps positional accuracy at low and high feed rates.

• Low friction with or without lubrication.

• Chemical resistant to a broad range of lubricants and coolants.

• Minimises vibration through damping characteristics.

• Low abrasion on running surfaces.

• High wear resistance.

• Good tensile strength and impact resistant.