Precision Machine Tool Alignments:

We have invested heavily in precision machine tool alignment and calibration aids. We can offer at very competitive prices the following services: Ballbar, laser and traditional granite square and DTI alignment methods.

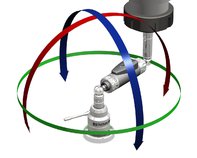

What is a Renishaw ballbar?

The Renishaw QC20-W ballbar system consists of the ballbar itself which essentially a very high accuracy, telescoping linear sensor with precision balls at each end with precision magnetic mounts. One is attached to the machine table and the other to the machine spindle or spindle housing.

In use the balls of the sensor are kinematically located in the magnetic cups. This arrangement enables the ballbar to measure minute variations in radius as the machine follows a programmed circular path around the mount on the machine table.

The data collected is sent to a laptop, where Renishaw's software calculates overall measures of positioning accuracy such as circularity and circular deviation in accordance with international standards such as ISO 230-4 and ASME B5.54 or in Renishaw’s own analysis reports. This report uses a unique mathematical analysis to diagnose many additional individual machine errors from the set of linear readings. Data is displayed graphically as well as in numeric format to aid and support diagnosis.

- Bluetooth wireless technology ensures no wire handling issues, closed door operation and reduced possibility for system damage.

- New hardware and software which allows a 'partial arc' (220°) test. This gives you greater test flexibility including

- Improved Z axis testing

- Tests where axis travel is limited (typically Z axis on machining centres and X axis on lathes)

- Ability to test 3 planes from a single set up, using 'partial arc' tests for 2 of the tests and present a 'volumetric analysis'

- Faster data reading for enhanced analysis on small test circle and high feed rates.

- Enhanced software includes many new features for extended testing and greater ease of use.

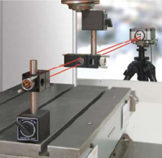

What is a Renishaw XL-80 Laser Interferometer?

The Renishaw XL-80 laser interferometer offers the ultimate in high performance measurement and calibration for motion systems, including CMMs and machine tools

Accuracy and dynamic performance

Linear measurement accuracy is an assured ±0.5 ppm thanks to a precision stabilised laser source and accurate environmental compensation. Readings can be taken at up to 50 kHz, with a maximum linear measurement speed of 4 m/s and a linear resolution of 1 nm, even at maximum speed. All measurement options (not just linear) are based on interferometric measurements, giving confidence in the accuracy of the data recorded.

Ease of use

The XL-80 is quick and easy to set-up and use, reducing waiting time and increasing available measurement time, whilst still retaining the accuracy benefits of a pure interferometry based system.

Increase machine uptime

Whatever your machine or motion system, you need to know that it is up to the job - before you even begin cutting or processing material or measuring components. You can gain a detailed picture of how each characteristic of a machine's positioning performance is varying over time. Predict when maintenance work will be required for specific machines, and establish contingency plans in advance.

Improve machine performance

Renishaw's performance measurement equipment can actually improve machine performance through targeted maintenance and error compensation.